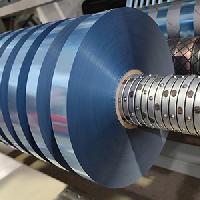

Customized solutions for barcode ribbon slitting machines: to meet individual requirements

Posted by slittermachine

from the Business category at

31 Mar 2025 02:12:02 am.

1. Customer demand analysis

• Industry differences: Different industries have different requirements for the specifications, materials, widths and lengths of barcode ribbons. For example, the logistics industry may require high-durability ribbons, while the retail industry is more focused on print clarity.

• Production scale: Small businesses may only need small-batch, high-variety slitting equipment, while large enterprises need high-efficiency, high-automation equipment.

• Special requirements: Some customers may have special needs for slitting accuracy, slitting speed, or equipment compatibility.

2. The core elements of a customized solution

• Slitting accuracy: According to customer needs, slitting machines with different precision are provided to ensure that the edge of the ribbon is flat and burr-free, and meet the needs of high-precision printing.

• Slitting width and length: Support a variety of width and length slitting to meet the needs of different specifications of ribbons.

• Degree of automation: Provide different configurations from semi-automatic to fully automatic to meet customers' requirements for production efficiency.

• Compatibility: The device is compatible with a variety of ribbons (such as wax-based, mixed-based, resin-based) and supports different specifications of cores.

• Convenient operation: Provide user-friendly operation interface and quick tool change design, reduce operation difficulty and maintenance cost.

3. Support for technological innovation

• Intelligent control system: PLC or touch screen control system is used to realize accurate adjustment and storage of slitting parameters, which is convenient for customers to quickly switch production tasks.

• High-precision sensor: Real-time monitoring of the slitting process through high-precision sensors to ensure stable slitting quality.

• Energy-saving design: Adopt high-efficiency motors and energy-saving technologies to reduce equipment operating costs.

• Modular design: The equipment adopts a modular design, which is convenient for functional expansion or upgrade according to customer needs.

4. Customized service process

• Demand communication: In-depth communication with customers to understand their specific needs and usage scenarios.

• Scheme design: According to customer needs, we provide personalized equipment design schemes, including slitting accuracy, speed, automation degree and other parameters.

• Equipment manufacturing: equipment manufacturing is carried out according to the design plan to ensure that each link meets customer requirements.

• Testing & Acceptance: Rigorous testing is carried out before the equipment is delivered to ensure stable performance, and customers are invited to participate in the acceptance.

• After-sales support: provide installation and commissioning, operation training and long-term after-sales service to ensure that customers have no worries.

5. Advantages of customized solutions

• Meet diverse needs: Through customized design, we can meet the individual needs of customers in different industries and sizes.

• Improve production efficiency: Customized equipment can better adapt to the customer's production process and improve production efficiency.

• Cost reduction: Through accurate design, avoid functional redundancy, and help customers reduce equipment purchase and use costs.

• Enhance competitiveness: Provide customers with unique solutions to help them gain an advantage in the market competition.

6. Application cases

• Case 1: Logistics industry

A logistics company needed a high-durability ribbon for barcode printing in an outdoor environment. The customized slitting machine adopts high-precision slitting technology to ensure that the edge of the ribbon is flat, and the equipment has high-speed slitting capacity to meet the needs of mass production.

• Case 2: Retail industry

A retail business needed ribbons in multiple widths for different product labels. The customized slitter supports quick tool changes and multi-width slitting, which significantly increases production flexibility.

conclusion

The customized solutions of the barcode ribbon slitting machine can effectively meet the individual needs of customers and help them improve production efficiency and product quality. Through technological innovation and high-quality services, manufacturers can provide customers with more competitive customized equipment and promote the sustainable development of the barcode ribbon industry.

0 Comments