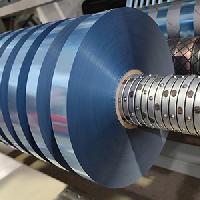

Copper foil slitting machine for lithium battery: help the development of new energy industry

Posted by slittermachine

from the Agriculture category at

28 Mar 2025 02:47:22 am.

1. High-precision cutting

Lithium batteries have extremely high requirements for the precision of copper foil, and the special slitting machine can achieve high-precision cutting at the micron level, ensuring that the size and shape of the copper foil meet strict standards, thereby improving the performance and consistency of the battery.

2. Efficient production

With the rapid development of new energy vehicles and energy storage systems, the demand for lithium batteries has increased significantly. The dedicated slitting machine has high-speed cutting capabilities, which can greatly improve production efficiency and meet the needs of large-scale production.

3. Automate operations

The equipment is equipped with advanced automatic control system, which can realize automatic feeding, cutting, winding and other operations, reduce manual intervention, reduce production costs, and improve the automation level of the production line.

4. High material utilization

By optimizing the cutting path and reducing scrap, the dedicated slitter is able to maximize the utilization of copper foil, reduce material waste, and save costs.

5. Stability and reliability

The production of lithium batteries places extremely high demands on the stability and reliability of the equipment. The dedicated slitting machine uses high-quality materials and advanced manufacturing processes to ensure that the equipment remains stable in long-term operation, reducing the failure rate and downtime.

6. Adapt to a variety of specifications

Lithium batteries come in a variety of specifications and models, and the dedicated slitting machine can flexibly adjust the cutting width and length to meet the needs of different specifications of copper foil and enhance the flexibility of production.

7. Environmental protection and energy saving

The equipment is designed with energy conservation and environmental protection in mind, and meets the requirements of green manufacturing by optimizing energy consumption and reducing waste generation, contributing to sustainable development.

summary

The copper foil slitting machine for lithium battery has significantly improved the efficiency and quality of lithium battery production through the characteristics of high-precision cutting, efficient production, automatic operation and high material utilization, and has provided strong support for the development of the new energy industry. With the continuous growth of the new energy industry, the equipment will play a more important role in the future.

0 Comments