Unveil the high-precision slitting technology of the slitting machine

Posted by slittermachine

from the Business category at

19 Feb 2025 08:58:06 am.

1. The core element of high-precision slitting

• Cutting accuracy: ensure that the slitting size error is controlled at the micron level.

• Edge quality: The cutting edge is smooth and burr-free, which meets the high quality requirements.

• Stability: Maintain consistent cut quality over long runs.

• Adaptability: Ability to handle a wide range of materials (e.g. film, paper, metal foil, etc.) and different thicknesses.

2. Key technologies to achieve high-precision slitting

(1) High-precision tool system

• Tool material: Carbide, ceramic or diamond-coated tools to ensure wear resistance and sharpness.

• Tool design: Optimize tool geometry, reduce cutting resistance, and improve edge quality.

• Tool adjustment: Equipped with a fine adjustment device to achieve precise control of tool clearance.

(2) Tension control system

• Closed-loop control: high-precision sensors are used to monitor the material tension in real time, and the material tension is automatically adjusted by servo motor or magnetic particle brake.

• Segment control: Set tension control in the unwinding, slitting and winding links to ensure that the material remains stable during the slitting process.

(3) Deviation correction device

• Automatic deviation correction: The photoelectric or ultrasonic sensor is used to detect the position deviation of the material, and the deviation correction roller is driven by the servo motor to adjust it in real time.

• High response speed: This ensures that the guiding system can respond quickly to changes in material position and avoid cutting deviations.

(4) High-precision transmission system

• Servo motor drive: High-precision servo motor is used to ensure accurate control of slitting speed and position.

• Linear guide and ball screw: reduce clearance and error in mechanical transmission, and improve slitting accuracy.

(5) Intelligent control system

• PLC control: Precise setting and automatic control of slitting parameters are realized through programmable logic controller (PLC).

• Human-Machine Interface (HMI): Provides an intuitive operator interface for easy parameter setting and fault diagnosis.

• Data collection and analysis: Monitor the slitting process in real time and optimize slitting parameters through data analysis.

(6) Visual inspection and feedback

• In-line inspection: High-resolution camera and image processing technology are used to detect slitting quality and dimensional accuracy in real time.

• Automatic feedback: The inspection results are fed back to the control system, and the slitting parameters are automatically adjusted to ensure consistency.

(7) Environmental control

• Temperature and humidity control: Operate in a constant temperature and humidity environment to reduce the deformation of materials caused by environmental changes.

• Dustproof measures: Keep the equipment clean to avoid dust affecting the slitting accuracy.

3. Application field of high-precision slitting

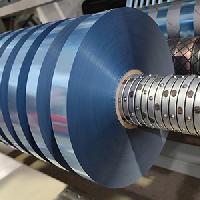

• Film industry: such as lithium battery separator, optical film, packaging film, etc.

• Paper industry: such as label paper, specialty paper, toilet paper, etc.

• Metal foil industry: such as copper foil, aluminum foil, etc.

• Composite materials industry: such as carbon fiber, glass fiber, etc.

4. The development trend of high-precision slitting technology

• Intelligent: Combining artificial intelligence and machine learning technology to achieve autonomous optimization of the slitting process.

• High speed: On the premise of ensuring accuracy, the slitting speed is increased to meet the needs of mass production.

• Multi-functional: Develop slitting equipment that adapts to a variety of materials and processes to improve equipment utilization.

• Green: Adopt energy-saving design and environmentally friendly materials to reduce energy consumption and environmental pollution.

summary

High-precision slitting technology has achieved a significant improvement in slitting accuracy and quality through advanced tool systems, tension control, deviation correction devices, intelligent control systems and visual inspection technologies. With the continuous development of technology, slitting machines will play an important role in more fields and promote the manufacturing industry to move towards high efficiency, high quality and intelligence.

Tags: slitting machine

0 Comments