From beginner to proficient: slitter operation skills and experience sharing

Posted by slittermachine

from the Business category at

14 Feb 2025 03:23:43 am.

First, the introductory stage: master the basics

1. Safety first:

• Familiarize yourself with the safety operating procedures of the equipment and understand the location of the emergency stop button.

• Wear necessary protective equipment such as gloves, goggles, etc.

• Ensure that the work area is clean and tidy, and avoid clutter affecting the operation.

2. Know the equipment:

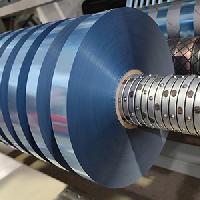

• Learn the basic structure of the slitting machine, including unwinding, slitting, winding and other parts.

• Familiar with the control panel, master the basic operations such as starting, stopping, speed adjustment, etc.

• Learn about the different types of blades and where they can be used.

3. Preparation of Materials:

• Select the right material according to the needs and inspect its surface for defects.

• Ensure that the width and thickness of the material meet the requirements of the equipment.

4. Basic Operations:

• Correct installation and adjustment of the blade to ensure slitting accuracy.

• Master unwinding and winding tension control to avoid material deformation or breakage.

• Perform simple slitting operations to familiarize yourself with the performance of the equipment step by step.

Second, advanced stage: improve skills

1. Parameter optimization:

• Adjust slitting speed, tension and other parameters according to material characteristics to ensure slitting quality.

• Gain experience by recording parameter settings for different materials.

2. Precision control:

• Use professional tools to calibrate the equipment to ensure slitting accuracy.

• Regularly check the wear of the blade and replace it in time.

3. Troubleshooting:

• Learn how to identify and deal with common faults, such as material misalignment, blade wear, etc.

• Master basic equipment maintenance skills such as cleaning, lubrication, etc.

4. Efficiency Improvement:

• Optimize operational processes and reduce downtime.

• Increase efficiency with automation features such as auto-guide, auto-roll change, etc.

Third, mastery stage: experience accumulation

1. Materials Research:

• In-depth understanding of the properties of different materials and their impact on slitting.

• Adjust the process parameters according to the material characteristics to improve the slitting quality.

2. Problem Solving:

• Ability to quickly analyze and solve complex problems such as slitting burrs, material delamination, etc.

• Propose equipment improvement suggestions to optimize the slitting effect.

3. Experience Sharing:

• Summarize the operation experience and form a standardized operation process.

• Train new employees and share how-to tips.

Fourth, other recommendations

• Keep the equipment clean and maintain it regularly.

• Pay attention to industry trends and learn new technologies.

• Communicate with peers and share experiences.

From beginner to proficient: slitter operation skills and experience sharing

Summary:

The operation of the slitting machine requires a combination of theory and practice, and through continuous learning and accumulation of experience, the operation level can be gradually improved, and the goal of mastery can be finally achieved.

Tags: slitting machine

0 Comments