The Application and Development of Aluminum Sheets in the Automotive Industry

Posted by alusale

from the Automotive category at

11 Nov 2024 07:58:44 am.

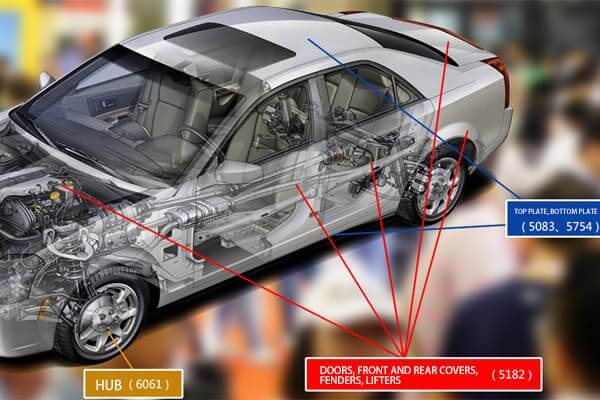

As a representative material of automobile lightweight, aluminum has become a key raw material for the development of the automobile industry to reduce the weight of the car body.

Aluminum Sheet For Car have the advantages of light weight, high strength, good tensile properties, corrosion resistance, etc., and are good materials for automobile manufacturing and parts processing.

Aluminum plate for four doors and two coversRecommended alloy: 5182 aluminum plate

While reducing the noise of the engine, the hood of the car can also isolate the heat generated by the engine when it is working, effectively protect the paint on the surface of the hood, prevent aging, and protect the engine and surrounding pipeline accessories.

Under the hood, is an important part of the car, including the engine, circuit, braking system, transmission system, which is very important to the vehicle.

By improving the strength and structure of the hood, it can fully prevent unfavorable factors such as impact, corrosion, rain, and electrical interference, and fully protect the normal operation of the vehicle. The corrosion resistance of 5182 aluminum plate determines that the car hood “will be used without it”.

Aluminum Plate For Four Doors And Two Covers

Aluminium alloy models for car roofs, bottom guards and gas tanksRecommended alloys: 5083, 5754, 5052 aluminum alloy sheets.Auto parts cover a wide range. Developed 5083, 5754, 5052 aluminum alloy plates and other light aluminum alloy products, which are used in automobile bottom guard plates and automobile fuel tanks.

5083 aluminum plate and 5052 aluminum alloy are widely used in these auto parts, with good practical application effect and good market response.

Aluminum sheet for automobile engine heat shieldRecommended alloy grades: 1060, 1050 alloy

Recommended alloy state: O

Application: It is suitable for producing various stamping parts such as automobile engine heat shield, heat shield parts, engine heat shield, automobile water tank, exhaust pipe heat shield parts, etc.

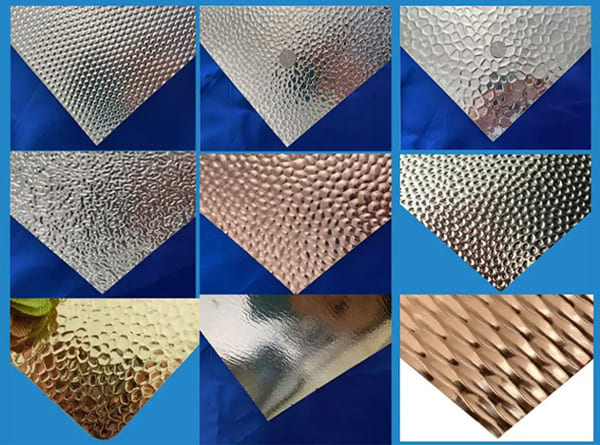

Preferred Embossed Aluminum Sheet:Embossed aluminum plate is an aluminum product with various patterns on the surface after calendering, and it is widely used. The embossed aluminum plate can increase the length and area of heat exchange with the outside air. On the premise of ensuring its good thermal conductivity, aluminum alloys should reduce costs as much as possible, and select corrosion-resistant materials for processing.

Preferred Embossed Aluminum Sheet

What are the advantages of aluminum alloy for automobile engine heat shield:- Good thermal insulation effect;

- Easy to disassemble, install, clean and maintain;

- Reusable and long service life;

- Anti-vibration;

- High strength, that is, soft and tough, and closely fit with the exhaust pipe;

- It can be customized according to the local position of the exhaust pipe;

3003 aluminum plate is a widely used power battery shell material, which belongs to aluminum-manganese alloy. It has excellent formability, high corrosion resistance, good weldability and deep drawing performance, and is easy to stretch and form aluminum casings for power batteries.

Aluminum shells are mainly used for square lithium batteries. Compared to steel shells, aluminum shells are lighter in weight and can be made thinner. In addition, the aluminum shell alloy material has obvious safety properties.

The battery aluminum shell made of 3003 aluminum plate has the characteristics of corrosion resistance, impact resistance, good punching and tensile properties, and is not easy to crack and leak.

1235 aluminum foil and 1060/1070/1100 aluminum foil are recommended for battery cells.

3003 Aluminum Sheet For Car

Composite panels for automotive water cooling panels3003:3003+40453003mod:3003mod+4343

New energy vehicle water cooling panels are used in load-bearing and corrosion-resistant environments and conditions. Therefore, it is necessary to develop high-strength, corrosion-resistant brazing composites to meet the design and application requirements of different water-cooled plates.

3003 aluminum plate has excellent performance and is widely used as a water-cooling plate material for automobiles. 3003 aluminum plate belongs to the series of aluminum-manganese alloys, which has the advantages of good corrosion resistance, low density, high specific strength, and easy processing and forming. It is an ideal lightweight material for automobiles.

As the country vigorously develops new energy vehicles, the demand for water-cooled plates will continue to rise, and the market demand for 3003 aluminum plates for brazing composite materials will also continue to rise.

Aluminum plate for car battery trayRecommended alloy grade: 6061

The new energy vehicle battery tray is the skeleton of the battery system, which can play the role of shock resistance, vibration resistance and protection to other systems. The battery tray has gone through different stages of development, from the initial steel box to the current aluminum alloy tray, and is developing to the more efficient copper alloy battery tray.

6061 Aluminum Sheet For Car

The aluminum alloy battery tray is made of 6061 aluminum plate. Aluminum alloy battery tray has high rigidity, impact resistance, impact resistance and other properties. Its weight is further reduced compared to steel pallets. The battery tray of this structure is usually used for small energy battery packs.6061 aluminum plate is used for the aluminum tray of automobile new energy battery, which belongs to aluminum magnesium silicon alloy. It has moderate strength, good corrosion resistance, weldability and good oxidation effect. The 6061 aluminum plate is used as the raw material of the battery aluminum tray, which meets the requirements of high precision, corrosion resistance, high temperature resistance and impact resistance.

Aluminum plate for new energy vehicle chassisRecommended alloy grade: 6061

A car can be said to be a movable electromechanical complex whose components come from a variety of materials. New energy vehicles are new types of vehicles that change the traditional power source and use their own quantitative materials.

Whether it is the battery, motor, electronic control of the three electric cores, or the chassis, body, and interior of the car, they are all made of the most basic materials. Therefore, energy saving and emission reduction is actually starting from materials to reduce the weight of the body, so as to achieve the purpose of energy saving and emission reduction.

Aluminum Sheet For Car

Among many materials, magnesium alloys and aluminum alloys are better lightweight materials. Mainly used for car body, chassis and most parts, these materials have characteristics and high quality manufacturing process.HUAWEI Aluminum Co., Ltd. can produce ultra-wide and ultra-thick 6061 aluminum plates, eliminate internal stress, and cut without deformation, with a width of 2650mm and a thickness of 500 mm. It is one of the few manufacturers in China that can produce ultra-wide and ultra-thick aluminum plates.

0 Comments

Aluminum Plate For Four Doors And Two Covers

Aluminum Plate For Four Doors And Two Covers Preferred Embossed Aluminum Sheet

Preferred Embossed Aluminum Sheet 3003 Aluminum Sheet For Car

3003 Aluminum Sheet For Car 6061 Aluminum Sheet For Car

6061 Aluminum Sheet For Car Aluminum Sheet For Car

Aluminum Sheet For Car