The basic knowledge and development process of slitting machine

Posted by slittermachine

from the Business category at

19 Oct 2024 05:51:10 am.

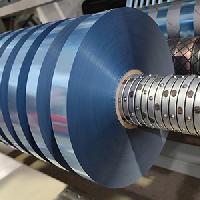

In the modern packaging industry, the slitting machine is a relatively important equipment often used before and after press, and it mainly slits raw materials such as paper, plastic film and so on before press. This is a process that must be completed by raw material manufacturers in order to meet the width requirements of customers and other packaging manufacturers. The most widely used slitting process after printing and compounding, the slitting machine is used to cut the printing and composite film of multiple groups of patterns with a fixed width into finished film rolls, so as to adapt to the automatic packaging and bag-making process in the back.

With the improvement of flexible packaging automation, and consumer goods manufacturers focus on reducing the inefficiency and pollution of intermediate links, some manufacturers have gradually changed the process flow and replaced manual packaging with automatic packaging lines with a higher degree of automation. With the increasing demand for coils, the position of the slitting machine is becoming more and more important, which puts forward higher requirements for the working efficiency of the slitting machine.

When it comes to the working efficiency of the slitting machine, many people think that the working efficiency of the slitting machine is only related to the speed of the slitting machine, but in fact, I think the working efficiency of the slitting machine is related to the following factors: slitting speed, yield, non-operating occupation time, stability, etc. Although the slitting speed is an important indicator of the working efficiency of the slitting machine, if the yield is low, it will not only cause the work efficiency of the whole machine to be low, but also cause the cost to rise. Similarly, if the non-operation occupies a long time, such as: machine adjustment, tool setting, tool change, material change, joint, roll change, processing problems and other long time, it is meaningless to simply improve the speed of the slitting machine. Not to mention the stability of the slitting machine, which will not only affect the working efficiency of the slitting machine, but also affect the product quality, and will cause trouble and unnecessary waste to the next process. So the working efficiency of the slitting machine is a comprehensive concept.

In the slitting process, the stable tension system is an important indicator to ensure product quality, which controls the mutual tension between unwinding, traction, slitting, rewinding, etc., so that the slitting material is always in a stable state in the slitting process. If the tension is properly controlled, it can avoid the deformation and drift of raw materials in the process of increasing and decreasing the speed of the machine. Generally, the unwinding tension is slightly greater than the sum of the winding shaft tensions. Most of the previous slitting machines use magnetic powder clutches to control tension, but the speed of magnetic powder clutches can not be high, which is easy to cause high-speed friction of magnetic particles during operation, produce high temperatures, shorten its life, and in serious cases, it will be stuck, so that the operation of the machine is blocked. With the development of science and technology, the use of servo drive technology, now most of the vector frequency conversion motor is used to control the tension system of the slitting machine, the use of pendulum roller automatic detection, the man-machine interface is intuitive, the tension system is more stable and reliable, easy to operate.

Tags: slitting machine

0 Comments