Understanding Room Ionisers, Autoclaves, ESD Testing, And Static Control

Posted by lambaleo

from the Business category at

19 Oct 2024 03:22:49 am.

Room ioniser: neutralising particles and purifying air

Purifying the air and regulating the presence of undesired particles depend on a room ioniser, which is also indispensable. These devices create negative ions that bind to airborne particles like dust, pollen, germs, even stationary electricity. The charged particles then gather together and either neutralise themselves or descend to the earth, therefore improving the air quality and safety.

Room Ionisers: Uses and Advantages

Room ionizer are especially useful in settings like cleanrooms, labs, and electronics production plants when air quality is vital. They lessen the presence of airborne pollutants, therefore offering a safer workplace.

Room ionizers assist in neutralising static charges in environments vulnerable to ESD, therefore preventing harm to delicate electronic components.

Room ionizers help to enhance air quality by eliminating allergens and pollutants, therefore lowering respiratory difficulties and producing a better indoor environment.

An autoclave is a high-pressure tool used in sterilising equipment and materials via high temperature steam exposure. In research, pharmaceutical, and healthcare environments when contamination control is absolutely important, it is extensively employed. In settings that call for sterile tools, autoclaves are necessary since they destroy bacteria, viruses, fungus, and spores rather well.

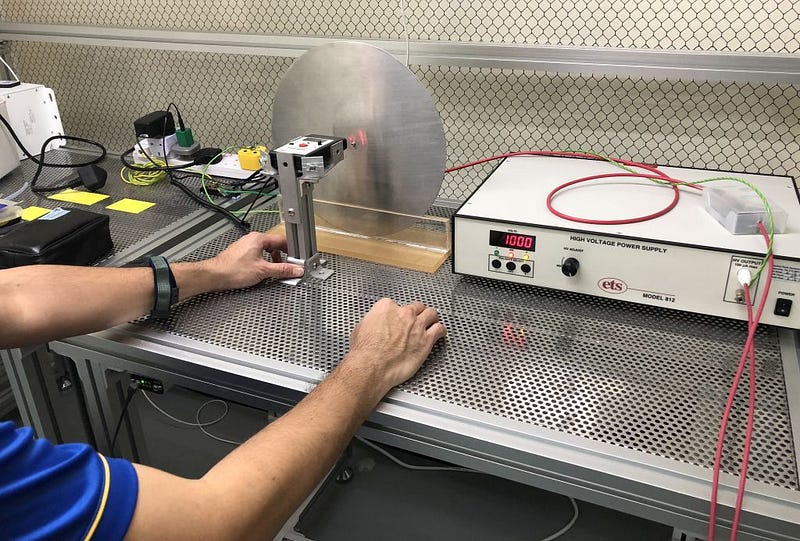

ESD Testing: Preserving Electronic Components

Industries engaged in the manufacture of electronic components depend critically on electrostatic discharge (ESD) testing. Sensitive electronic components may be damaged or degraded by static charge accumulation, therefore causing failures or malfunction. ESD testing guarantees that the surroundings are safe for electronics and helps to identify the possible hazards.

An ESD audit is an all-encompassing assessment of a company to guarantee it satisfies the required criteria for Electrostatic Discharge control. Companies handling sensitive electronic components or working in fields where ESD presents a major danger depend on these audits.

Static Control: Reducing Electrostatic Discharge

Static control is the application of tools and equipment meant to either avoid or neutralise the development of static electricity. Maintaining product integrity and operational safety depends on static management in settings where ESD could damage tools or equipment.

Why Do AMC Analyzers Matter?

In sectors like semiconductor production, the presence of AMCs could cause contamination affecting the quality of products. By constantly monitoring air quality and spotting possible problems before they impact output, AMC analyzers assist to preserve rigorous environmental standards.

Conclusion

A mix of specialised equipment including room ionisers, autoclaves, and ESD testing tools allows one to keep a controlled atmosphere in sensitive sectors. Understanding the value of ESD audits, static control, and monitoring airborne pollutants using AMC analysers helps companies to guarantee the health of their staff and the safety of their goods.

0 Comments