Features of automatic slitting machine

Posted by slittermachine

from the Business category at

25 Sep 2024 06:12:16 am.

Fully automatic tension control of the slitting machine

The tension control of the slitting machine is to keep the tension of the material conveyed constant by appropriate means. In the past, the slitting machine relied on manual control of tension, and in the process of winding and unwinding, the tension was manually adjusted according to the change of the roll diameter, and the accuracy of this method was poor, and it was difficult to achieve the purpose of stabilizing the tension. The constant tension control system automatically adjusts the optimal tension during the curling process of the material and keeps it constant. There are many common tension control schemes, such as detecting and feeding back the tension through the tension sensor, and automatically controlling the actual tension to be equal to the preset value to achieve stable tension. It is also possible to set up a floating roller, detect the position of the floating roller through the potentiometer, and automatically adjust the tension to keep the position of the floating roller unchanged to keep the tension constant. It can also adjust the output torque of the inverter to achieve taper control by adjusting the output torque of the inverter, and finally obtain constant tension control, which is widely used in the automatic tension control of high-speed slitting machine.

Fully automatic correction control of the slitting machine

As a closed-loop feedback control system, the automatic deviation correction system has become the standard configuration of the slitting machine. According to the different correction objects, the slitting machine can be divided into three correction methods: EPC edge control, LPC marking line control, and CPC center position control. Edge guiding is generally used for materials with neat edges. Marking lines are usually used in the printing and packaging industry to track the color marking lines on materials. Center position correction is used for the occasion when the edge of the material is not uniform or the width is inconsistent, and the deviation of the center line is detected to achieve automatic deviation correction control.

The automatic correction system of the slitting machine generally includes a correction sensor, a correction controller and an actuator. The actual position of the substrate is detected by the sensor, and when the position is offset from the reference position, the correction controller sends instructions to the sliding actuator according to the analysis calculation, and automatically brings the material back to the reference position. With the development of slitting machines, the requirements for deviation correction accuracy and response speed are also increasing.

Semi-automatic loading/unloading of slitter machine

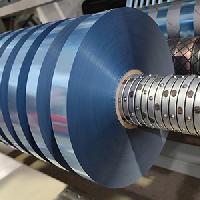

Feeding refers to the installation of the film roll to be slitted on the unwinding shaft, which has developed from the traditional manual feeding to the semi-automatic feeding method with the help of a crane or cylinder. In addition, Delish Machinery changes the shafted unwinding to shaftless unwinding, that is, replacing the traditional slip shaft or inflatable shaft with the unwinding chuck, which is more convenient for the film. The small shaft slitting machine is generally equipped with a discharge rack, and when discharging, the rotating discharge arm is docked with the winding shaft, and the finished film roll is pushed to the discharge frame manually or automatically to complete the unloading process. For the winding and slitting machine with a large material width (generally more than 2 meters) and an independent station, the unloading can also be carried out in a shaftless winding method to improve the unloading efficiency.

Other automatic control of slitting machine

With the development of intelligent digital technology, more and more automatic control technology is integrated into the production and manufacturing of slitting machines. The application of automatic film threading and automatic knife arrangement technology greatly saves manual operation time and eliminates the possibility of misoperation. The turret type four-axis slitting machine realizes automatic film breaking, automatic roll changing, and does not affect the operation of the slitting machine while discharging, and improves production efficiency. The automatic packaging line uses a robot to transport the parent roll to multiple slitting machines through the conveyor belt in turn, and each slitting machine will transfer the slitted finished film roll to the sorting equipment and complete the final packaging. The automatic slitting machine solves the problem of efficiency and consistency through automation technology, and further realizes intelligence on the basis of automation.

0 Comments